Boiler forced-draft-fun and Inducet-draft-fan are suitable for ventilation systems of industrial boilers with various coal materials as fuel and equipped with smoke and dust removal devices, which can be selected and used in all the occasions with appropriate air coming conditions and performance.

For G4-73 boiler forced-draft-fanit is not allowed to have temperature of air delivered over 80DC . For Y4-73 boiler inducet-draft-fan, temperature of air delivered is generally not over 250°C.

Centrifugal fan generally consists of parts of air inlet, impeller, scroll case, outlet, gearing device, base and motor.

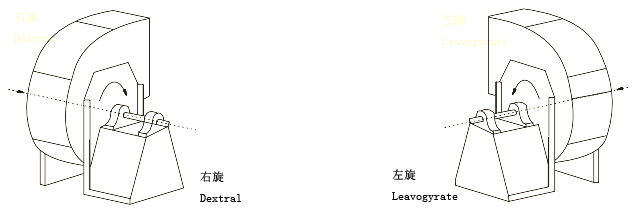

Centrifugal fan is divided into dextral fan and laevogyrate fan according to rotary direction of impeller. It is called dextral fan and expressed with right if front view from one side of motor or gearing device finds impeller rotates clockwise, and called laevogyrate fan and expressed with left if front view from one side of motor or gearing device finds impeller rotates counter-clockwise.

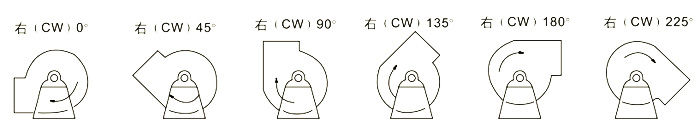

Location of outlet of centrifugal fan is expressed with the angle of outlet of mantle. The adjustment scope of location of outlet of centrifugal fan is generally 0 degree to 225 degrees and the space is 45 degrees. Information about angle of outlet will be provided upon goods ordering.

Common driving types of fan are as follows:

Driving Type A: centrifugal fan is not set up with gearing device,motor and impeller drive in connection.

Driving Type C: centrifugal fan is set up with gearing device, impeller and pulley are respectively located at both ends of gearing device, motor drives through pulley.

Driving Type D: centrifugal fan is set up with gearing device, impeller and clutch are respectively located at both ends of gearing evice, motor drives through clutch.

(Remarks: Figuration of fan and its installation chart are shownon the table below.)

In case that the application status is not coincident withspecificstatus in the performance table or blower's rotatingspeed changes, it is necessary to convert performance of application status into that of specific status in the performance table, and then select blower according to converted performance.

When the fan is newly installed, phenomena of over-sufficient or insufficient volume flow occur in formal operation mainly because of the following:

1.Difference between actual value and calculated value of pipe network resistance is too big. It is known from formula of regular pipe network characteristics of P=KQ2 that if the actual value of K, the coefficient of pipe network characteristics, is less than the calculated value, the volume flow will increase, rf the actual value of K is more than the calculated value, volume flow will decrease.

2.In selection of fan impact of , warp of total pressure value of fan itself is not considered. When the actual total pressure of fan is positive warp, volume flow will increase, and when the actual total pressure of fan is negative warp, volume flow will decrease. Warp of volume flow of fan can be eliminated through the following methods:

(1)Adjusting volume flow with throttling gear, for example, with air damper or shutter.

(2)Changing speed adjustment volume flow of fan's impeller.

(3)Replacing with adjustment volume flow of fan with higher pressure or lower pressure.

(4)Changing adjustment volume flow of pipe network resistance. It is necessary to point out: throttling gear is generally adopted to adjust volume flow of fan. But when the actual volume flow is much more than the required volume flow, it will cause much waste of electric power and will be very uneconomical. If possible, reduction of fan speed or replacement of fan with lower pressure should be adopted. When throttling gear is in full operation, if volume flow is still too small, it means that the throttling gear is out of effect, and it is necessary to change pipe network to reduce resistance so as to increase volume flow. It is also possible to adopt methods of increasing speed of fan impeller or replacing with fan with higher pressure. However, the maximum speed of fan should not exceed the maximum speed in the performance table and it is necessary to calculate motor power.

6.NOTICE TO GOODS ORDERING:

To order goods, please indicate the use environment of fan, required pressure, volume flow and fan size, rotary direction, angle of outlet, driving type, impeller rotate speed and motor model, etc.

Our factory provides special design and manufacturing upon user's request.

hits:3126

hits:3230

hits:3346

hits:3495

hits:3224

hits:3233

hits:3234

hits:3168

hits:3247