Centrifugal fan is generally used for indoor ventilation of large buildings such as factories, and for high pressure forcible ventilation of boilers and forging boilers and other occasions of materials handling. Types of gas handled by centrifugal fan is air or other non-explosive and noninflammable gas and gas non-corrosive to steels. Stickum should not be contained in gas, dust and hard corpuscular matter contained should not be larger than 150mg/m3. Temperature for gas handling should not exceed

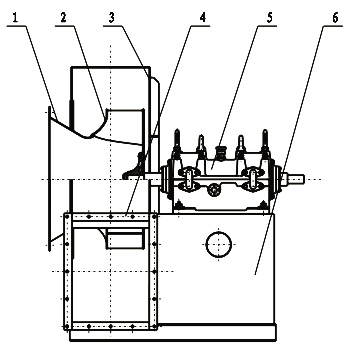

Sketch map of structure of centrifugal fan

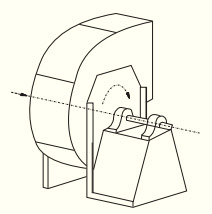

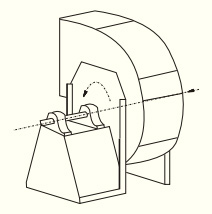

Centrifugal fan is divided into dextral fan and laevogyrate fan according to rotary direction of impeller. It is called dextral fan and expressed with right if front view from one side of motor or gearing device finds impeller rotates clockwise, and called laevogyrate fan and expressed with left if front view from one side of motor or gearing device finds impeller rotates counterclockwise.

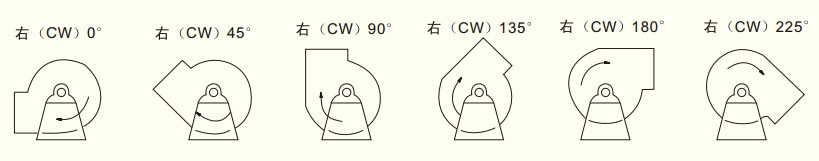

Laevogyrate (Impeller rotates counter-clockwise) Location of outlet of centrifugal fan is expressed with the angle of outlet of mantle. The adjustment scope of location of outlet of centrifugal fan is generally 0 degree to 225 degrees and the space is 45 degrees. Information about angle of outlet will be provided upon goods ordering.

Common driving types of fan are as follows:

Driving Type A: centrifugal fan is not set up with gearing device, motor and impeller drive in connection.

Driving Type C: centrifugal fan is set up with gearing device, impeller and pulley are respectively located at both ends of gearing device, motor drives through pulley.

Driving Type D: centrifugal fan is set up with gearing device, impeller and clutch are respectively located at both ends of gearing device, motor drives through clutch.

(Remarks: Figuration of fan and its installation chart are shown in the table below.)

hits:3127

hits:3230

hits:3347

hits:3495

hits:3224

hits:3233

hits:3234

hits:3168

hits:3247